How Feeding and Charging System Optimizes Material Use

Feeding and Charging System is no longer a futuristic concept – it is the practical route RONGKE uses every day to tame alloy costs, stabilize chemistry, and protect margins in foundries and steel shops worldwide.

Why Traditional Charging Falls Short

For decades, melt-shop managers have battled a simple equation: unpredictable scrap plus conservative alloy additions equals runaway costs. Manual charging crews often work under intense time pressure, gauging raw material quality by eye while loaders hurry to keep furnaces hot. Even a small overdose of alloy chips away at profit, while an under-dose invites scrap, rework, and unhappy customers.

A closer look at the pain points shows why incremental fixes rarely move the needle:

•Inaccurate batching data – Operators rely on static spreadsheets or even paper logs that ignore daily scrap swings.

•Delayed feedback loops – Lab results arrive after the heat is tapped, so corrective alloys pile on top of yesterday’s mistakes.

•High labor intensity – Repetitive shoveling of ferro-alloys and iron fines erodes morale and invites safety incidents.

•Energy drain – Each unnecessary tap or trim heat prolongs furnace time, raising power bills and electrode wear.

These realities are the backdrop against which RONGKE developed its integrated Feeding and Charging System. Instead of fighting variability, we let smart sensors, algorithms, and mechatronics turn it into predictable advantage.

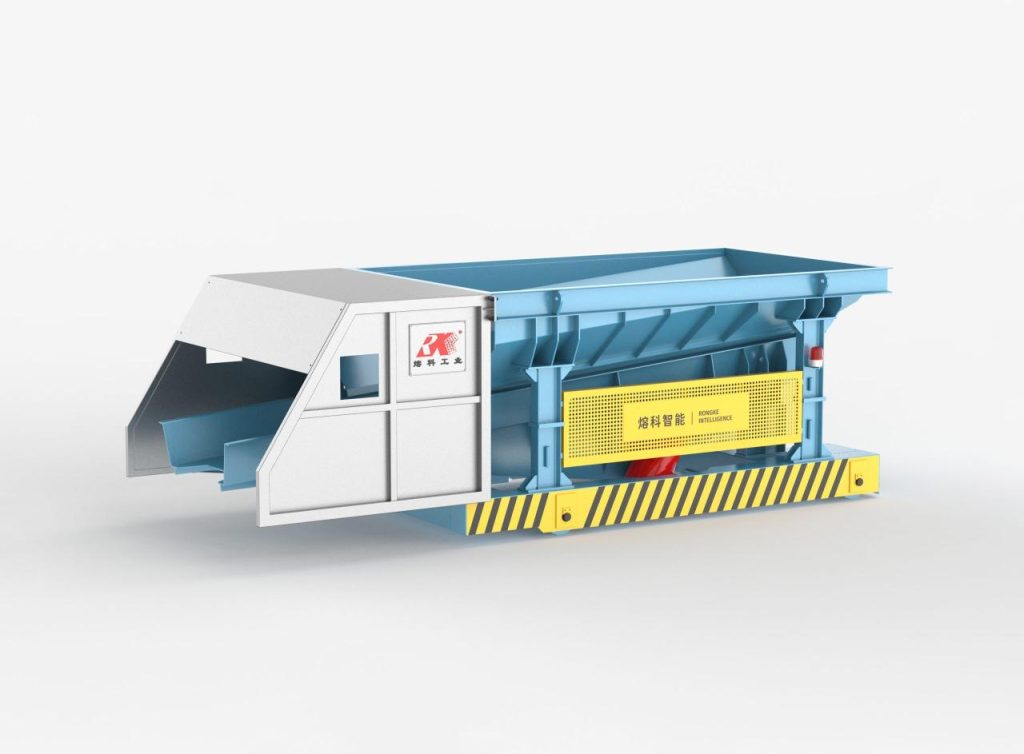

Inside RONGKE‘s Feeding and Charging System

• Automatic Iron Batching

At the heart of our automatic iron batching solution is a radar-guided crane that scans every corner of the raw-material yard. Whether the bin contains pig iron, returns, or low-carbon scrap, position and weight data stream into a rules engine that calculates the ideal blend for the next heat. The crane’s electromagnetic disc removes the guesswork, laying the charge with millimeter accuracy into the vibrating cart. Operators no longer play “mix-and-match” with scrap grades; they watch a live dashboard confirm that carbon targets will be met on the first melt.

• Intelligent Alloy Control

Precise iron is only half the story. Alloy additions are where cost control becomes profit protection. Our algorithm factors metal grade, desired chemistry, and current bath composition to schedule the exact moment and quantity of ferro-silicon, manganese, and inoculant. Because the system links directly to your spectrometer, it continuously refines its recipes – a closed loop we call alloy cost reduction technology. The payoff is twofold: alloy spend drops, and chemistry variation tightens, yielding fewer downgrades and re-melts.

• Real-Time Monitoring and Data Loop

Sensors embedded in the cart, bin gates, and furnace mouth feed synchronous updates to the control station. Instead of waiting for the shift report, supervisors see the health of every batch – weight, temperature, time at power – displayed in plain language KPIs. When something drifts, the logic engine nudges the next feed, notifies the operator, and logs the event for traceability. The result is a calmer floor, smoother melts, and measurable energy savings.

Not every advantage needs bold headlines; many are felt in everyday decisions. Consider these user-proven gains:

•Alloy overdosing trimmed by double-digit percentages.

•Charging cycle time shortened, freeing furnace capacity for extra heats.

•Labor redeployed from shoveling to quality analytics, boosting job satisfaction.

•Safety metrics improved as operators step away from hot lips and swinging buckets.

• Custom Fit, Not One-Size-Fits-All

No two melt shops share the same mix of scrap sources, furnace sizes, or grade portfolio. That is why RONGKE engineers start with an on-site study, mapping existing flows and pinpointing the highest-impact loss points. From there we configure bin volumes, gate designs, and cart footprints that respect your building envelope and maintenance culture. Our modular PLC platform speaks the language of mainstream automation brands, so integration with legacy ladle furnaces, ladle dryers, or baghouses is straightforward.

From Cost Center to Profit Driver

An investment in a Feeding and Charging System is more than a cap-ex line; it is a path to cultural change. Teams shift from firefighting to forecasting, from rule-of-thumb additions to data-driven precision, and from siloed departments to a single digital backbone.

RONGKE customers often describe three stages of transformation:

✅Stabilize – The system ends material guesswork, so chemistry drifts disappear and alloy reconciliations balance.

✅Optimize – Real-time insights let managers experiment with cheaper scrap blends, knowing the algorithm will protect quality.

✅Expand – Freed furnace hours open room for new grades or third-party toll melting, turning yesterday’s cost center into tomorrow’s revenue stream.

We understand that approving new automation can feel risky. That is why we offer a phased rollout: begin with an audit, continue with a pilot on one furnace, then scale plant-wide once savings are proven on your floor, with your scrap, and your team’s hands on the controls.

Ready to See the Difference?

RONGKE’s engineers are only a click away. Schedule a no-obligation virtual tour of an installed Feeding and Charging System, or request a melt-shop simulation using your current alloy mix. Boost productivity, cut alloy waste, and lift safety – all without adding headcount. That is the promise of RONGKE‘s Feeding and Charging System. Let us turn your next heat into the start of a leaner, smarter future. Contact us now and take control of your alloy costs today.