Why Copper Melting Induction Furnaces Are in High Demand

China has a fast-growing industrial sector. It needs more and more refined copper. This growing need is very strong. Copper melting induction furnace has become important for this reason. In the past, people used traditional melting methods. But they were not very efficient. They also used a lot of energy. These problems made factories look for better ways. Many companies wanted to find new solutions. So, the push for cleaner and faster methods started. Now, innovation leads the industry forward.

Rongke: A Leader in Copper Melting Induction Furnace Manufacturing

A Modern Industrial Enterprise

Rongke is a modern industrial enterprise. It works on technology research and development. It also focuses on boiler manufacturing, installation, and maintenance. Rongke is based in China. It brings together experience from many fields. This helps Rongke create strong products for the market. It always aims to provide better and safer solutions.

Years of Dedication to Advanced Solutions

Rongke has many years of dedication. It specializes in advanced induction furnace solutions. The copper melting induction furnace is built with more interactive windows. It also has more detailed quality designs. The technology level is very high in the industry. Rongke focuses on better materials and improved processing techniques. It also leads in crafting skills. These efforts make sure the production process is safer, more stable, and more energy efficient.

A Strong Reputation

Rongke has built a strong reputation. It is known for offering tailored solutions. It delivers efficient and eco-friendly furnace technology. Many clients trust Rongke because of its attention to detail. It always aims to create better furnaces for modern needs.

Unique Techniques: Rongke‘s Technological Edge

IDE Furnace Leakage Alarm System

Rongke has developed the IDE furnace leakage alarm system. This system is very safe and reliable. It has a patented design and EU CE safety certification. The IDE system watches the furnace full-time and from all directions.

Its leakage detection works in two ways. First, if molten iron seeps from the furnace lining, it touches the current detection electrode. Then, the alarm sounds. Second, if the molten iron reaches the coil, the voltage detection circuit sounds another alarm and shows the location.

The grounding alarm system works simply. If molten iron gets close to the coil, the system senses a higher leakage current. If the coolant becomes too conductive, the system also triggers an alarm. These features make the copper melting induction furnace much safer to use.

Leading Energy Saving with Better Coil Design

The coil is the heart of the furnace. Rongke uses TU1 grade oxygen-free copper. It gets this copper from Chinalco Luoyang Copper Co., Ltd. The coil is made with the thickest wall copper tube. This tube is produced by a cold extrusion process. Rongke combines it with double coil technology. This design makes the copper melting induction furnace more energy efficient. Because of these efforts, the furnace saves more energy than others. Rongke’s focus on the best materials helps it lead the industry again and again.

Advanced Magnet Yoke Technology

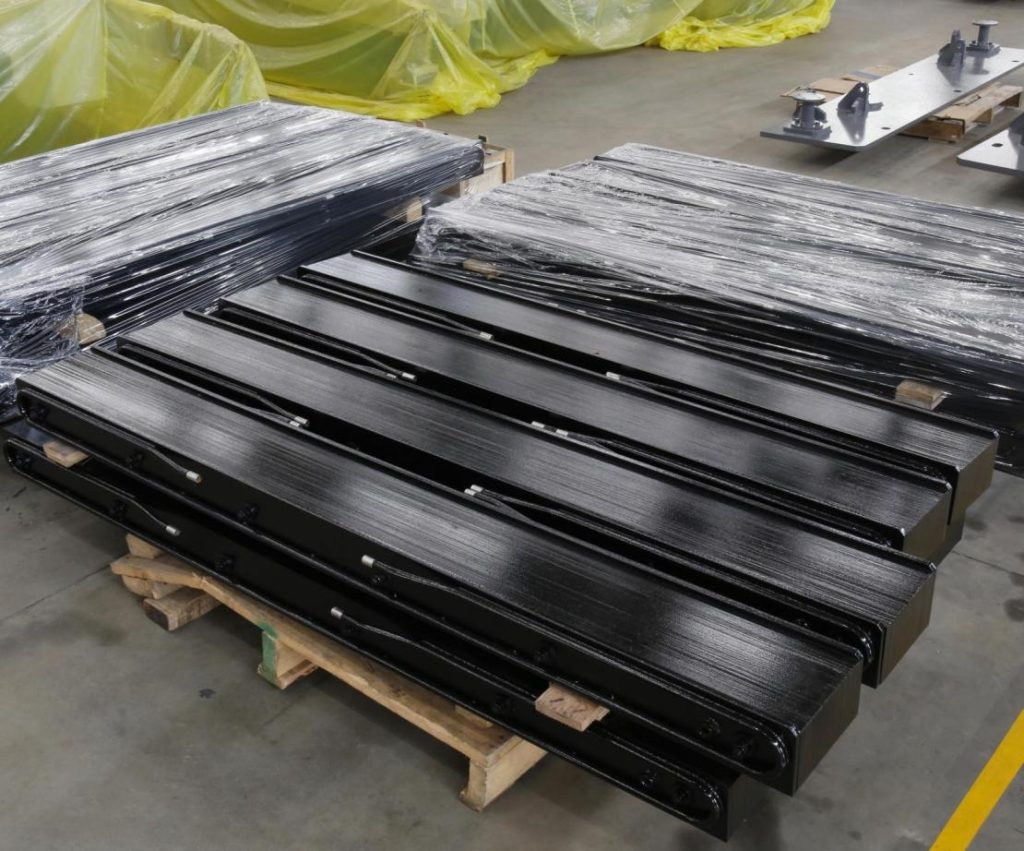

Rongke also uses special magnet yoke technology. The magnet yoke is made with high-quality cold rolling directional silicon steel sheets. It keeps magnetic loss very low, less than 105. The coverage rate of the magnet yoke is higher than 70%. The magnet yoke supports the induction coil from all directions. It gathers the magnetic field into the molten bath. Water flows through both sides of the yoke. This keeps the temperature balanced. It also improves the working life of the system. The magnet yoke has two jobs. It cools and it supports the coil. It is also maintenance-free. The use of premium silicon steel and smart design leads to low magnetic loss. It creates less heat and has a long working life. These features make the copper melting induction furnace much more reliable.

Product Spotlight: The “Intermediate Frequency Coreless Induction Furnace”

Tilting Furnace Drive System

The tilting furnace drive system is very important. Rongke uses a hydraulic oil pump. One pump works, and one stays on standby. All oil cylinders have explosion-proof valves. They also have protective covers. All exposed oil pipes are wrapped with fire-proof sleeves. This design makes the system safe and reliable. It also ensures that the copper melting induction furnace can work in harsh environments without problems.

Cooling System

The cooling system is well designed. It uses enclosed distilled water for cooling. Every waterway is equipped with water temperature and pressure monitoring. Rongke uses German Continental brand carbon-free rubber pipes. These pipes are strong and safe. The cooling system is connected to the leakage alarm system. If something goes wrong, the system can react quickly. This protects the copper melting induction furnace and keeps the operation stable.

360 Type Dust Hood

The 360 type dust hood is special. It is driven by double hydraulic rods. It stays stable during use and does not flutter. It can open and close in many directions. It has strong suction power. This design helps control dust very well. It also keeps the working environment clean. A clean environment means better safety and longer equipment life for the copper melting induction furnace.

Key Advantages of Rongke‘s Intermediate Frequency Coreless Induction Furnace

Lower Noise

The copper melting induction furnace made by Rongke is very quiet. Its noise is 30% lower than similar products. This makes the workplace more comfortable. It also helps workers focus better and feel less tired.

Fully Enclosed Furnace Shell

The furnace shell is fully enclosed. This design stops dust from causing coil ignition. It also protects the inside parts from pollution. It makes the furnace safer and helps it last longer. The fully enclosed design is one big reason why Rongke’s copper melting induction furnace stands out.

Lower Magnetic Radiation

The closed furnace shell also provides a second layer of magnetic shielding. This cuts down magnetic radiation. The amount of magnetic radiation is only 10% of what similar products create. This number is far below the national standard. It makes the working area safer for everyone. Rongke shows great care for worker health through these designs.

Application Fields: Versatility of the Furnace

Electrical Engineering

The copper melting induction furnace is widely used in electrical engineering. It helps manufacture cables and wires. Copper needs to be pure and well-melted for these products. Rongke’s furnace makes sure the molten copper is clean and high quality. This is very important for good electrical conductivity.

Automotive Sector

The furnace is also important in the automotive sector. Copper parts are everywhere in cars. Connectors, motors, and many electronic parts need good copper. Rongke’s copper melting induction furnace provides stable melting results. This ensures that copper components meet strict industry standards.

Art Foundries and Precision Casting

Many artists and precision casters love this furnace too. It helps produce fine, decorative, and industrial copper pieces. Precision and stability are key in these fields. The copper melting induction furnace by Rongke offers both. It helps create beautiful and functional copper products with ease.

Boost Your Productivity with Smarter, Greener Solutions from Rongke!

Ready to upgrade your production with safer, smarter, and greener solutions? Rongke’s copper melting induction furnace delivers the power and efficiency modern industries need. Join the companies already boosting their productivity and leading the market. Let Rongke help you meet today’s demands and build a stronger future.

Contact us today and take the first step toward smarter copper melting!