How Automatic Batching Systems Cut Costs and Errors

Automatic batching systems bring a new level of precision to production. They blend ingredients in exact proportions every time. This means less waste and fewer mistakes. You save money and time with simple setup and steady output.

Many companies struggle with manual processes. Mistakes happen, materials get lost, and costs rise. Automatic batching systems solve these problems. They work quickly, follow exact recipes, and need less supervision. Over time, this leads to lower labor costs and better product quality.

If you’re looking to boost productivity and reduce errors, it’s time to consider automation. In this article, we’ll explore how automatic batching systems can transform your operations – making them smarter, faster, and more reliable.

Why Precision Matters in Modern Manufacturing

The Hidden Cost of Inaccuracy

In today’s competitive industrial landscape, traditional batching methods fall short. Manual or semi-automated processes often result in material waste, production delays, and inconsistent product quality. Overuse of expensive raw materials or underuse that compromises product standards both translate into unnecessary costs. Moreover, labor-intensive corrections and rework further drain resources. When batching errors occur, the ripple effect can be felt across the entire production cycle – leading to lost time, increased operational expenses, and reduced customer satisfaction.

Rising Demands

As global markets push for higher output and more refined product standards, manufacturers are expected to deliver greater volumes without compromising quality – or inflating costs. Customers demand reliability and consistency in every batch. Meanwhile, factory managers must juggle limited resources and increasing expectations. Meeting these demands calls for smarter, data-driven systems that improve accuracy, automate decision-making, and optimize performance at every stage.

Smarter Manufacturing with Rongke‘s Automatic Batching Systems

At Rongke, we design intelligent automatic batching systems that bring clarity, control, and precision to your production floor. Built for modern challenges, our systems are engineered to reduce material waste, minimize labor costs, improve energy efficiency, and deliver consistent output. The result? Smarter manufacturing, better margins, and higher customer satisfaction.

Core Advantages of Automatic Batching Systems

Precision Raw Material Control

Using high-accuracy sensors and weight control systems, our batching solutions manage every gram of raw material with precision. This ensures that each batch falls within exact specifications – avoiding both excess use and shortages. Consistent input leads to consistent output, improving both product quality and process stability.

Real-Time Monitoring and Feedback

Our systems offer continuous real-time monitoring. As soon as any variable changes – be it weight, material flow, or temperature – the system responds immediately. This real-time feedback loop reduces human error, corrects deviations on the spot, and maintains optimal conditions throughout the process.

Flexible Customization for Unique Production Needs

Every factory is different. Whether you’re handling powders, liquids, alloys, or granules, Rongke’s systems are fully customizable. We tailor each solution to match your specific material types, batch sizes, and production goals. This adaptability makes it easier to integrate our systems into existing workflows and keeps you agile in a changing market.

Alloy Batching System: Smart Metal Management

Optimized Alloy Usage

Our alloy batching solution uses real-time data to determine the precise amount of alloy required based on the composition of raw materials. This ensures that every batch aligns with target metal specifications, eliminating both excess usage and performance gaps.

Dynamic Adjustment with Spectrum Analysis

The system is tightly integrated with spectrum analyzers that continuously assess metal content. If any deviation is detected, the system adjusts the batching plan instantly. This automatic recalibration ensures your alloy composition remains accurate and within spec, without the need for manual intervention.

Efficient Use of Resources

By delivering just the right amount of each alloy element, the system minimizes material waste and reduces overall costs – without sacrificing quality. This balance of cost control and performance is vital in high-value metal industries.

Intelligent Iron Batching: Precision at the Core

Radar-Guided Material Location Detection

To further reduce guesswork and human error, Rongke’s iron batching system uses radar positioning to detect the exact location and quantity of raw materials. This ensures that the right material is selected every time – boosting accuracy and reliability.

Seamless Material Handling with Crane and Disc Integration

Once located, materials are automatically picked up and transferred using a coordinated travel crane and electromagnetic disc. This fully automated process removes the need for manual handling, enhancing safety, reducing labor demands, and ensuring smoother transitions.

Batching Based on Composition Requirements

Our intelligent system reads the production formula and matches it with current raw material characteristics. It then develops a batching strategy that meets exact needs with fewer errors. This ensures every batch supports consistent product quality from the ground up.

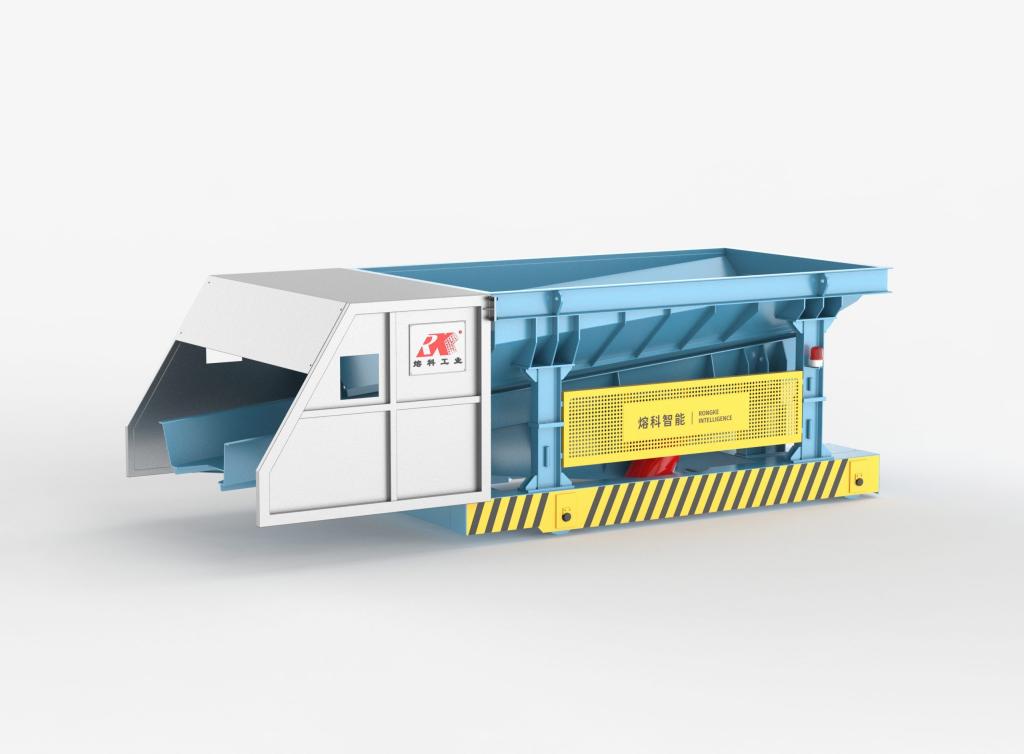

Automation in Feeding: The Charging Cart System

Dual-Bin Vibration Cart for Flexible Feeding

At the heart of our material feeding system is a vibration charging cart with dual bins – one for alloy, one for iron. This setup allows for flexible sequencing and accurate control over feeding order, ensuring compatibility with various production schedules and material types.

Integrated Communication with Melting Furnaces

The cart is fully linked with both the batching system and the melting furnace, maintaining a real-time feedback loop. This synchronized operation ensures timely material delivery, reduces idle time, and boosts overall furnace efficiency.

Safe, Consistent Feeding

By automating the feeding process, our system eliminates splashing, material segregation, and sudden dumps – reducing workplace hazards and improving operator comfort. This also enhances feeding accuracy and process stability.

The Power of Real-Time Data Management

Live Monitoring Across the Production Line

With Rongke’s systems, you gain complete visibility into your batching process. Every batch can be tracked live, giving operators the tools to intervene proactively if something goes off course. This transparency is key to maintaining process integrity.

Adaptive Batching with Automated Adjustments

As raw material conditions change, our system automatically adjusts its parameters to maintain target compositions. This eliminates the need for manual recalculations and prevents production interruptions – saving both time and money.

Comprehensive Data Logging and Reporting

All process data is logged and stored, providing a traceable production history. This supports quality audits, process improvements, and future planning. With historical data at your fingertips, your team can make better decisions and continuously improve operations.

Conclusion: Precision Is No Longer Optional – It‘s Essential

In the age of smart manufacturing, precision and efficiency define success. Rongke’s automatic batching systems offer a scalable, intelligent solution for modern factories aiming to reduce waste, control costs, and deliver top-tier quality. Whether you’re working with alloys, iron, or complex material mixes, our systems bring unmatched accuracy and real-time intelligence to your operation – turning manufacturing challenges into competitive advantages.