How Automatic Batching System Transforms Small Industries

In modern manufacturing world, small industries are under increasing pressure to compete with larger players. Efficiency, precision, and cost control have become critical success factors. One of the most transformative technologies making this possible is the automatic batching system. This smart solution not only boosts productivity but also improves product consistency, reduces material waste, and minimizes labor costs.

As a manufacturer, Rongke, we’ve seen firsthand how automatic batching systems help small businesses achieve big results with limited resources. Our solutions are designed with precision, flexibility, and real-time monitoring at the core, making industrial batching and charging simpler and smarter.

What Is an Automatic Batching System?

Think of it as the factory’s brain and nervous system. Sensors weigh raw ingredients. Valves, screws, or cranes dispense them. A PLC or industrial PC runs the logic. Operators see everything on a touch screen or a phone. Data flows to ERP or MES software without extra typing.

Core Hardware Blocks

• Load cells with 0.05 % precision.

• RFID or QR readers for material ID.

• Servo-driven feeders for powders, chips, or pellets.

• Travel crane plus electromagnetic disc for irons and scraps.

• Vibration charging cart with dual bins for alloys and base metal.

Smart Software Layers

• Recipe management with version control.

• Real-time alarms for deviation beyond ±0.2 %.

• Automatic batch proportioning based on lab or spectrometer data.

• Cloud dashboard for KPI trends and remote service.

Precision Control: The Foundation of Quality

At Rongke, our automatic batching systems use advanced algorithms and sensors to calculate the ideal ratio of raw materials. Here’s how it works:

1) Iron Batching Automation

Our system evaluates raw material composition and production requirements. Then it automatically generates the best iron batching plan. Radar scanners detect the material positions, and the coordinated actions of an automatic travel crane and electromagnetic disc execute precise material transfer.

2) Alloy Batching Optimization

Alloy addition is one of the most sensitive steps in the smelting process. Too little affects quality; too much raises costs. Our automatic batching system:

✅ Calculates required alloy based on the chemical grade to be produced

✅ Links with spectrometers to adjust plans in real time

✅ Reduces alloy waste while ensuring product consistency

3) Real-Time Data: The Silent Productivity Engine

Data is only valuable when fresh. Our automatic batching system updates dashboards every second. Managers read live OEE scores on a tablet. Maintenance staff receive vibration and temperature alerts before a bearing fails. Accountants export CSV files straight to cost models. No more waiting until month-end to learn what went wrong.

Key dashboards include:

• Batch Accuracy Heat Map – Shows which shifts drift off target.

• Material Usage Pareto – Highlights top five waste drivers.

• Energy vs. Throughput Trend – Correlates kilowatt hours with tons produced.

By exposing hidden patterns, the system turns anecdotal hunches into agile action.

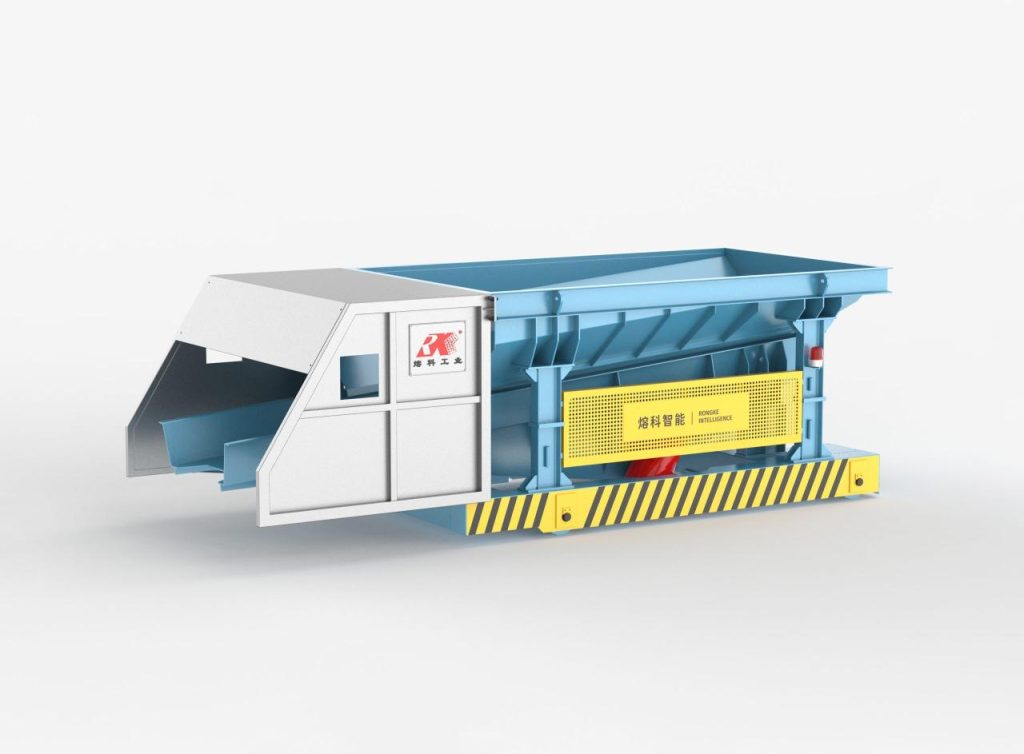

Customized Charging Cart System

We’ve also developed a vibration charging cart that integrates perfectly with the batching system. It features:

✅ Separate bins for alloy and iron

✅ Customizable charging sequence

✅ Real-time synchronization with melting furnaces

✅ Option for fully automatic or semi-automatic operation

This configuration ensures smoother material flow, better control, and reduced downtime in the production line.

Benefits of Automatic Batching & Charging Systems for Small Industries

Implementing an automatic batching system offers several key advantages that can completely change the trajectory of a small manufacturing business:

- Enhanced Efficiency

Processes that once required hours of manual work are now completed in minutes with superior accuracy.

- Consistent Product Quality

By controlling material ratios precisely, quality remains stable across all production batches.

- Reduced Material Waste

Smart sensors and AI-based adjustments prevent overuse of costly raw materials.

- Lower Labor Costs

Automation reduces dependency on manual labor, enabling teams to be smaller but more skilled.

- Improved Workplace Safety

Minimized human intervention in high-risk zones like smelting areas results in fewer accidents.

How Rongke Supports Small Manufacturers

At Rongke, we’re more than a supplier – we’re a partner in growth. Our automatic batching system solutions are tailored for small and mid-sized operations looking to:

✅ Expand their output

✅ Improve competitiveness

✅ Modernize outdated equipment

We understand that every customer has unique needs. That’s why our systems are fully customizable, with flexibility to adapt to various production demands, alloy types, and operational scales.

Industries That Can Benefit from Automatic Batching

While originally used in large steel and casting operations, today the automatic batching system is making a major impact across various small-scale industries:

• Foundries and metal smelting

• Chemical and plastics processing

• Food and beverage production

• Ceramics and building materials

• Pharmaceuticals and cosmetics

Whether you’re handling powders, liquids, or mixed materials, a Rongke batching solution can boost your operational efficiency and quality control.

Future-Proofing Your Workshop

Manufacturing is entering an era of hyper-personalization. Orders shrink from thousands to dozens. Compliance demands full traceability. An automatic batching system is the cornerstone for Industry 4.0 in small plants. Connect it to a digital twin tomorrow, or feed AI demand forecasts next year – the hardware stays the same.

Emerging options on our roadmap:

• Integration with humanoid robots for bag unloading.

• Blockchain batch certificates for export clients.

• Edge analytics to spot micro-stop losses in seconds.

Stay ready for whatever the market asks.

Conclusion: Empower Your Factory with Rongke

Small industries deserve big opportunities. With a Rongke automatic batching system, even modest manufacturing plants can achieve levels of productivity, quality, and cost efficiency previously out of reach.

Ready to upgrade?

Contact Rongke today to discover how our automatic batching systems can transform your production floor.