Saving Time and Money: The Practical Power of an Automatic Batching System

Today’s industries demand greater precision, faster operations, and improved consistency – and this need is only growing. Yet, traditional manual batching methods often fall short. They cause delays, introduce errors, slow down workflows, and waste valuable time, ultimately leading to significant financial losses.

To overcome these challenges, automatic batching systems have become essential. They boost speed, minimize mistakes, enhance production stability, and help businesses save both time and money. But what exactly can an automatic batching system do for your operation? Let’s dive deeper and find out.

Business Value: Why Companies Should Adopt an Automatic Batching System

Saving Costs

The automatic batching system helps companies save money. It reduces material waste. It also cuts down labor costs. As a result, businesses can use fewer resources and still get more work done.

Improving Product Quality

The automatic batching system makes products more consistent. It keeps the quality high every time. This builds a strong brand image. Customers trust the products more when they see good quality again and again.

Making Workflows Faster

The automatic batching system improves the whole production flow. It lets companies work faster and better. With smoother processes, businesses can grow and take on more work easily.

Why Rongke‘s Automatic Batching System Stands Out

Smart Batching Control

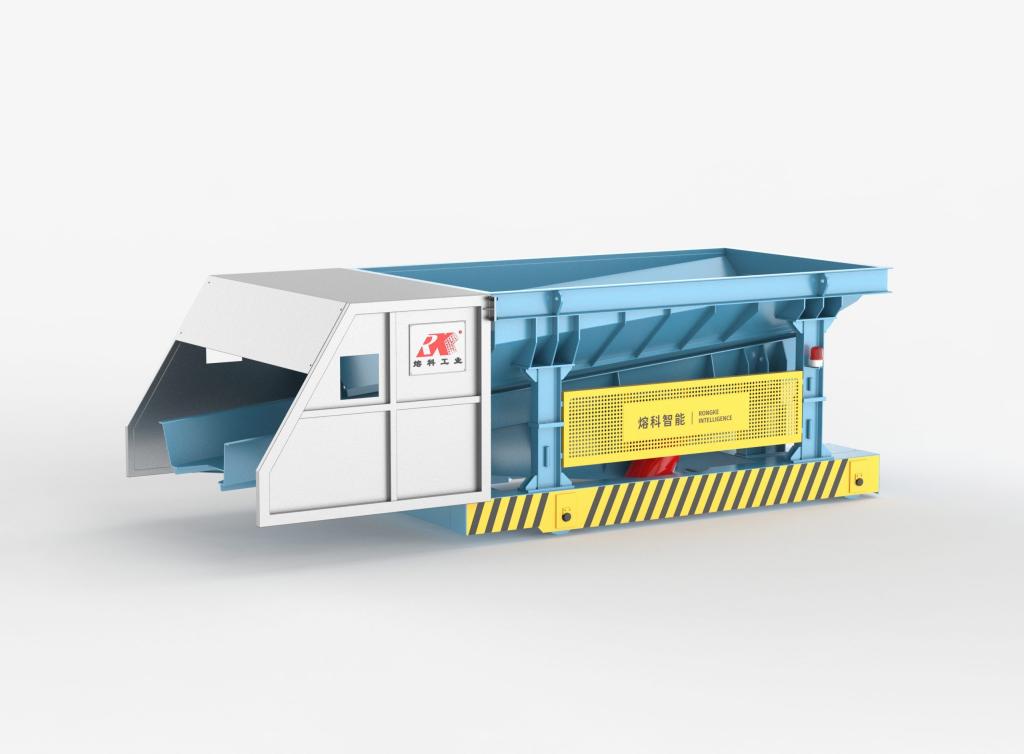

Rongke’s automatic batching system is designed with smart sensors and advanced control technology. It carefully measures raw materials to prevent waste and avoid shortages, ensuring precise batching every time. Using radar scanning, the system quickly identifies the positions of raw materials.

With the help of an automatic crane and electromagnetic disc, it completes the iron batching process with no need for manual intervention. This not only boosts efficiency but also improves workplace safety and consistency.

Real-Time Monitoring and Adjustments

Throughout the smelting process, Rongke’s system provides real-time monitoring. It constantly checks the composition of materials and automatically adjusts the batching plan as needed. By adding the right amount of alloy based on material quality and the required product grade, it keeps the molten iron within strict specifications.

The system can also work with a Spectrum Analyzer to optimize the batching formula even further. As a result, it reduces the consumption of expensive alloys while maintaining the strength and quality of the molten metal.

Easy Formula Management

Managing complex batching formulas has never been easier. Rongke’s system can store multiple batching recipes and automatically execute them according to production needs. All batching data is transmitted in real-time to an integrated computer system, allowing for seamless data tracking and management.

On-site workers can quickly access the information to analyze results, make informed decisions, and continuously improve the melting process, ensuring greater operational efficiency.

Precise Alloy Feeding

Precision is critical in alloy feeding, and Rongke’s system excels at it. It calculates the exact amount of alloy required based on real-time feedback from the production process. When connected with a Spectrum Analyzer, the system can immediately adjust batching ratios to match the changing needs of the molten metal.

An accurate alloy silo positioned above the furnace ensures that the right amount of material is added at the right time. Every batching plan is automatically saved into the system for easy reference and traceability, supporting quality assurance and process optimization.

Partnering with Rongke: A Smart Business Decision

Dedicated Project Management

Rongke gives each client a special project team. The team listens carefully to the client’s needs. Then, the team creates a plan that fits the client’s goals. Every solution is made to match the client’s real situation.

Strong Training and Support

Rongke offers full training for every customer. The team teaches how to use the automatic batching system step by step. After training, Rongke stays ready to help. Good support makes sure the investment keeps giving value for a long time.

Always New Technology

Rongke provides updates often. These updates bring better features and tools. This helps businesses keep ahead of their competitors. The automatic batching system gets smarter and stronger over time.

What Makes Rongke Special: More Than Just a Product

Customer-Focused Innovation

Rongke always listens to what customers need. They design the automatic batching system to grow with each business. As companies expand, Rongke’s system can change and improve to meet new demands.

Industry-First Certifications

Rongke reached important milestones early. They were the first to pass the EU CE certification. They also earned the ISO quality management certification. Rongke is proud to be a high-tech enterprise that leads the industry.

Full Industrial Power

Rongke is not just about making products. Rongke is a modern industrial company. They focus on technology research, boiler manufacturing, installation, and maintenance. All services work together to support the automatic batching system and much more.

Applications: Saving Time and Money with Rongke‘s System

Food and Beverage Industry

The automatic batching system helps food and drink companies a lot. It batches ingredients with high accuracy. This keeps food quality high and reduces waste. Businesses can make better products and save money at the same time.

Construction Materials Industry

In the construction world, the automatic batching system creates consistent material mixes. It makes sure every batch is right. This cuts costs and lowers the number of mistakes. Companies get stronger materials with less waste.

Chemical Production Industry

In chemical factories, safety is very important. The automatic batching system controls ingredients carefully. It follows safety rules and improves product quality. It also helps workers stay safe and work faster.

Elevate Your Business with Rongke‘s Automatic Batching System!

Transform the way you work with Rongke’s advanced automatic batching system. Save time, reduce waste, and maintain the highest product quality – all with one smart solution. Our expert team is ready to guide you with cutting-edge technology and reliable support. Accelerate your growth and stay ahead of the competition. Don’t wait – contact us today and discover how Rongke can drive your success!