Slow Production? Aluminum Melting Furnace For Sale

Aluminum Melting Furnace For Sale is more than a product listing; it is our promise that every RONGKE customer can cast faster, safer, and with greater peace of mind. As a manufacturer who has shaped induction technology from the inside out, we know that time lost in the melt shop echoes across the entire supply chain. Slow heating, unexpected leakage alarms, and soaring energy bills all erode profit and weaken competitiveness. In this blog we explore how choosing an advanced coreless induction solution removes these pain points, boosts casting agility, and opens fresh capacity without expanding your floor space.

Why the Right Aluminum Furnace Boosts Casting Speed

Every minute a ladle waits, resources drain away. Operators stand idle, dies cool, and delivery clocks keep ticking. A sluggish melt also causes metal segregation and hot-spot oxidation, leading to higher scrap and rework rates. Worse still, emergency overtime becomes the ”normal” way to hit deadlines, pushing labor costs through the roof and turning routine shifts into safety risks.

A coreless induction furnace heats the charge from inside the bath, not from the shell. This method eliminates flame contact and prevents localized superheating that weakens the lining. RONGKE’s intermediate-frequency system delivers a gentle, swirling motion that keeps the alloy homogeneous and pour-ready faster than resistance or fuel-fired designs. The result is steady throughput, shorter tap-to-tap cycles, and higher alloy recovery.

✅ Smooth electromagnetic stirring maintains even temperature and chemistry.

✅ Clean, flameless atmosphere slashes oxidation losses and reduces emissions.

✅ Flexible power control lets you ramp quickly for urgent jobs or hold gently during delays.

Slow melts are no longer the unavoidable bottleneck; they are a solvable engineering problem once you invest in an energy efficient aluminum melting furnace tuned for modern casting realities.

Inside the RONGKE Intermediate Frequency Coreless Induction Furnace

• Leakage-Proof Safety Design

At RONGKE we refuse to treat safety as an optional extra. Our patented full-time furnace leakage alarm forms a double shield around people, plant, and profit. The system senses when molten metal creeps beyond healthy limits and issues a clear, early warning long before the coil faces danger. Intelligent grounding detection adds another layer of protection by monitoring coolant conductivity and insulation integrity. This proactive approach means operators act on information, not on instinct.

✅ Early current-based alerts pinpoint lining wear before an actual break-out.

✅ Voltage-based zoning highlights the precise area requiring maintenance.

✅ Automatic interlocks shut down power if unsafe conditions persist.

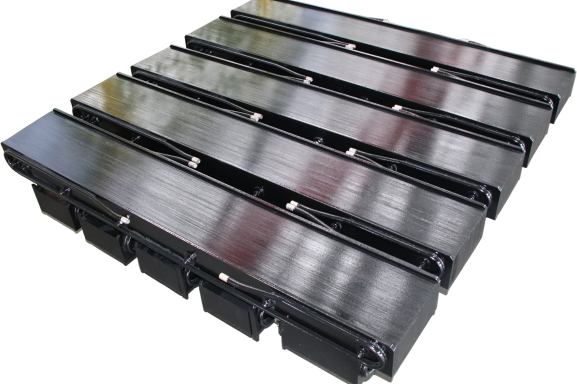

• Energy-Saving Coil and Magnet Yoke

We use TU1 oxygen-free copper tubes formed by cold extrusion. Their thicker walls cut resistance and improve heat exchange, while our double-coil arrangement shortens melt time without raising peak power demand. Surrounding the coil is a high-grade silicon-steel magnet yoke that gathers stray flux, guiding it back into the bath for higher electrical efficiency. Integrated water channels cool the yoke evenly and eliminate hot spots, so components last longer and maintenance intervals stretch farther.

✅ Superior copper purity reduces resistive losses and boosts thermal stability.

✅ High-coverage yoke concentrates the magnetic field exactly where you need it.

✅ Balanced water paths keep coil temperature uniform, preserving refractory life.

• Strong Supporting Systems, Stable and Worry-Free

A furnace is more than a coil; it is a coordinated ecosystem. Our hydraulic tilting drive uses dual pumps in active-standby mode, ensuring smooth pour control even during service checks. All cylinders are shielded by explosion-proof valves and fire-resistant hoses. An enclosed distilled-water circuit monitors temperature and pressure at every branch, triggering alarms if deviations occur. The optional 360-degree dust hood, hinged on twin actuators, captures fumes without fluttering, protecting operator lungs and local compliance.

Long days in the foundry are demanding enough. Equipment should remove stress, not add it. By addressing each potential weak link – drive, cooling, and dust capture – RONGKE delivers the most complete coreless induction melting furnace price-to-performance ratio on the market.

Ready to Accelerate Production? Your Aluminum Melting Furnace For Sale Awaits

• How to Contact RONGKE Today

The sooner you modernize, the sooner you reclaim your schedule. Whether you operate a high-pressure die-casting cell, a sand-casting line, or an aluminum recycling yard, the RONGKE team can tailor a specification that meets power supply, crucible volume, and automation needs. Tell us about your current melt rate, energy targets, and space constraints, and we will prepare a full proposal – including payback outlook and layout drawing – within days.

Call-to-Action: Take the first step toward hassle-free melting. Click here to request a live demonstration of our Aluminum Melting Furnace For Sale or email linda.nieh@cnrkgy.cn for a free technical review. If you prefer a quick benchmark, ask for our checklist on converting from gas to induction, or download the guide “Five Signs Your Furnace Is Holding You Back” – ideal reading for plant managers planning next year’s capital budget.

Final Thought

At RONGKE we believe that innovation only matters when it removes real-world pain points. Every weld seam on our fully enclosed shell, every magnet yoke lamination, and every line of control software aims at one simple promise: less waiting, more casting. When you invest in an Aluminum Melting Furnace For Sale from RONGKE, you invest in time – time your customers will appreciate and your competitors will envy.

Let‘s melt, cast, and grow – together.